After enjoying the warm and sunny weather in the south during the cold German winter months, I finally came back to Germany mid June. It was great to see my family and friends in southern Germany after almost half a year again. We went on mountain-bike trips, swimming, hung out and enjoyed the summer weather.

I was headed to the farm of my friends in Bavaria when one of my friends told me that they were spending a weekend at an alpine cabin near Zillertal in Austria. I decided to take a little detour, parked my van in the valley near Stumm and grabbed my mountain-bike to visit my friends on the alp. The ride was exhausting but fun.

The views were amazing!

After spending a relaxed weekend, hiking and enjoying the good weather, I finally arrived at the farm of my friends in Bavaria.

I had been cruising around for several months, so it was about time to maintain my van a little bit.

Renewing the chassis and underbody

The underbody and chassis were exposed to tough conditions on the Canaries: Rocky dirt roads and constant wind mixed with sand and salty water demanded a lot. Overall the van was in a good condition, so I wanted to make sure it stayed like that and decided to blast the chassis and underbody with dry-ice. I got in touch with Mark from Strahlzentrale München and a few days later, we removed all the dirt and the old undercoating.

To my surprise and joy, we didn’t find a lot of rusted metal. The tank, chassis, underbody and wheelhouses had been well conserved by the undercoating applied by the army in the 80s. However the undercoating was quite old and started to get brittle, so we removed all of it to apply a new layer of a wax to protect the entire chassis, underbody and wheelhouses.

We applied the wax on the wheelhouses,

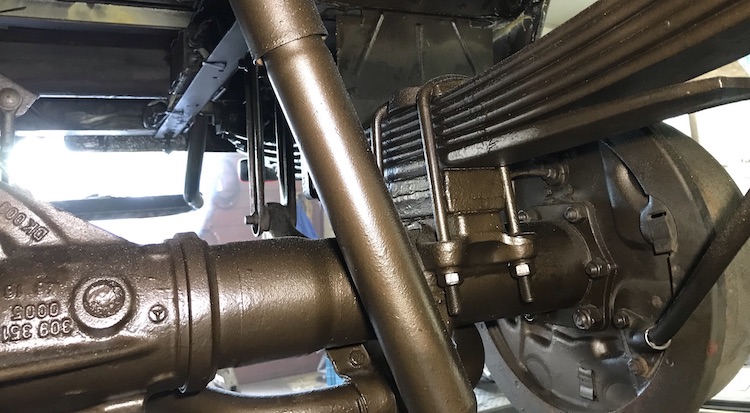

the axil and suspension in the front,

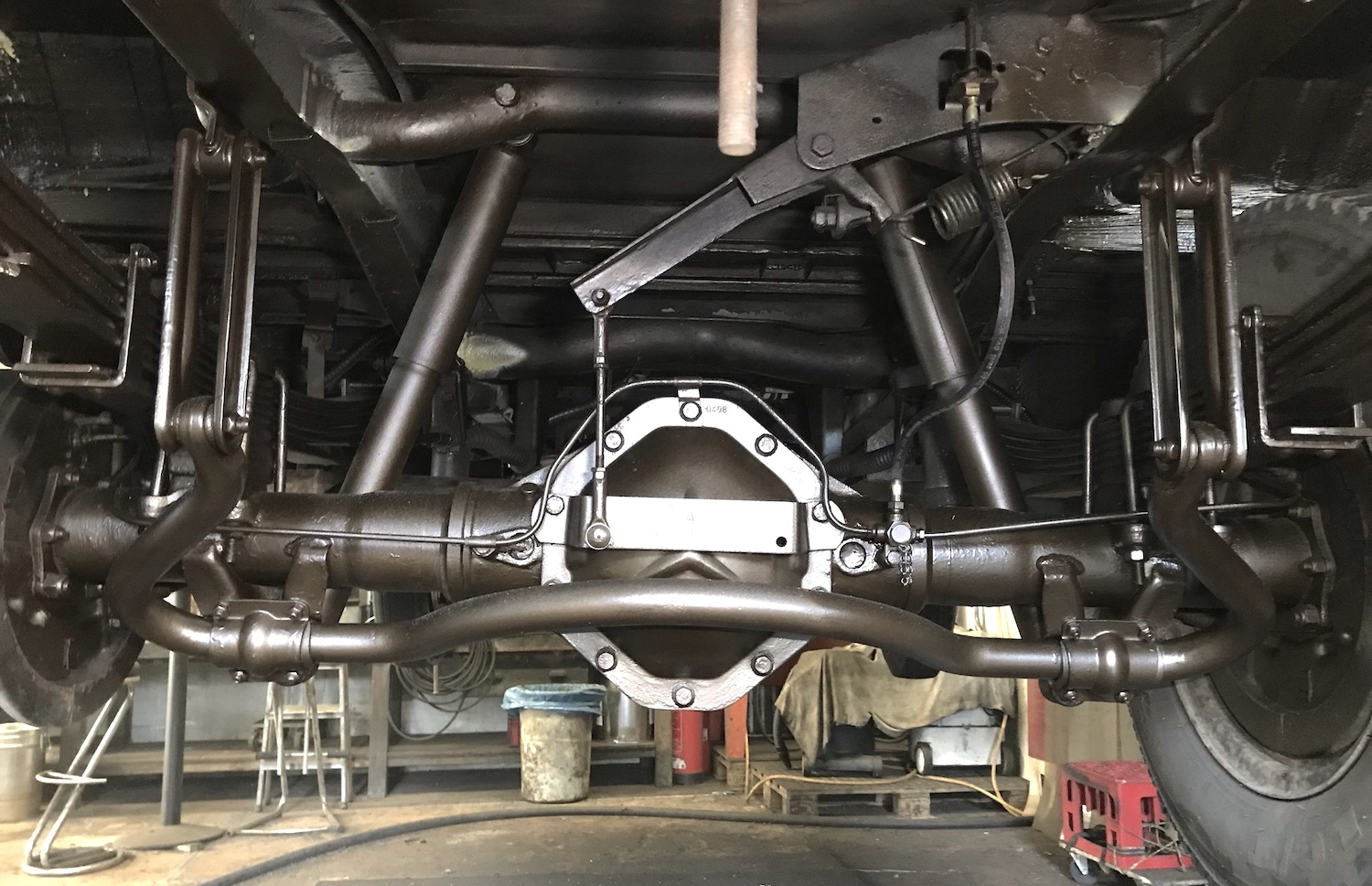

and in the back,

including the differential. We also sprayed anti-corrosion grease into all cavities. I was really happy with the result. The van looked like a brand new vehicle and seemed ready for the next trips! ![]()

Replacing the tie rods

When driving with high velocity, I could feel the steering wheel shaking a little bit. After driving for several thousand kilometers I could also observe that the tires were worn-out irregularly.

When inspecting the tie rods to adjust the wheel alignment, I realized that the rubber sleeve of both tie rods had cracks and leaked grease.

With the help of a big puller, I managed to remove the tie rods for which I found new replacements on the aftermarket.

The new tie rods looked much better. After installing them and properly aligning the wheels the steering wheel didn’t shake any more.

Iterating on the interior

Besides taking care of mechanical issues, I also worked on a few things inside the van. I had never gotten to the point of covering the insulation on the doors and the entrance steps.

Over the years the insulation had suffered from all the shoes hitting it, so I decided to protect the soft insulation with a durable fleece cover.

I also applied the fleece on the doors in the back to protect the insulation from getting damaged when pulling out the camping chairs or the mountain-bike.

I also iterated on the “office” in my van: The original table didn’t span the whole area between the two seats. After spending some time with Mariona working together in the van, we realized that a bigger table would offer much more comfort for two people working in the van at the same time, so I wanted to build a larger table.

I glued two pieces of oak wood together.

The freshly sanded and oiled table nicely fitted between the two seats and offered the maximum possible size. Working together on the new table felt much more comfortable! ![]()