The scaffold that is supposed hold the wooden cladding was one of the most challenging constructions that I’ve built for the van so far. Removing all the rust from the van during the summer was a lot of work. I really didn’t want to drill any holes into the metal underneath the roof and behind the gutter to avoid thermal bridges as much as possible. Additionally, I didn’t want to lose any vertical or horizontal space by mounting a scaffold onto the van’s steel ribs.

I checked a bunch of van blogs like Paul’s Passport Diary for inspiration. In most blogs I saw pictures where the cladding was screwed right into the van’s body or into a wooden scaffold that was mounted on top of the steel ribs. None of these examples satisfied my requirements: no loss of space and no screws that would connect the body and the air inside the van. ![]()

Designing my own solution

As previously described, I mounted beams on the horizontal steel ribs that would eventually allow me to mount the walls and furnitures without creating thermal bridges or losing any horizontal space.

I built wooden arches that exactly matched the height of the insulated steel ribs to prevent any loss of vertical space.

The arches were squeezed right into the insulated groove at the top of the van’s walls.

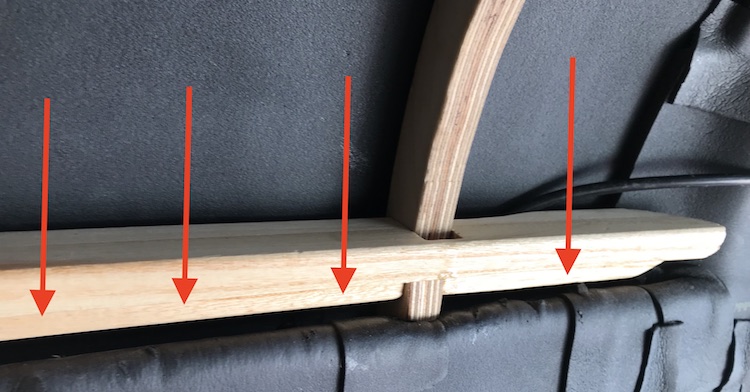

Custom L-shaped bars were supposed to be placed horizontally between the arches.

However, I had troubles squeezing the bars into the insulated groove, so I rounded all the corners and fitted each piece individually.

I glazed all the pieces to make sure they won’t bend because of the frequently changing humidity inside the van.

When the glaze was dry, I pushed the fitted L-shaped bars into the groove between the arches.

Squeezed into the groove, the bars stabilized the arches and provided a robust horizontal surface to mount the wall cladding.

I crafted some connectors out of aluminum that linked the single bars to further improve the stability of the whole construction.

I’m really happy with the result so far. The self-supporting scaffold seems very stable and is completely decoupled from the van’s body. The construction might admittedly be over engineered. But I really enjoyed doing all the wood work in the sunny streets of Berlin.